-It's not a complete refutal of LED, in case you're wondering. If that were the case, then this site wouldn't be called "stop LED streetlights."

-It's not an assumption that the past is perfect. It's easy to think this, but be assured that the technologies of yore had their fair share of disadvantages. However, they aren't important enough to really be mentioned here, or the big idea of SLS wouldn't exist.

Now that WTWIN is finished, let's get into the content you came here for.

Problem 1: Aesthetics

Many LED streetlights resemble things that aren't streetlights, such as tennis rackets, flyswatters, and waffle irons.

It's hard for me to say if this is a bad thing or not, but I think it can be odd to look at a light pole and see a weid-shaped item that shines right in your eyes.

Problem 2: Reliability

Many LED streetlights tout high reliability and long lives, but you aren't hearing the other side of the story. With most the traditional HID (non-LED) fixtures, you can simply change out a bulb and it's ready for some more years of illumination. However, with LED, the majority of them aren't as simple as this. A dead fixture could mean the whole thing being replaced, as replacing the driver can take a while compared to replacing a light bulb. What does it involve? Replacing a driver requires removing the screws that hold it in place, and then disconnecting its wires. Then, installing a new driver involves the same process but in reverse. A bulb can be quickly unscrewed and and the new one screwed in, and you're done.

Here's more about the driver:

If you don't know already, in order to run a streetlight, you need a ballast, sometimes called a driver. HID fixtures almost always use a magnetic ballast, with the exception of a few contemporary models that use an electronic version. Fundementally, the magnetic ones are some wire wrapped around a metal core, and then coated with varnish. As you might expect, this setup is very reliable, since it's very simplistic. Sometimes, they'll include a capacitor, but they last a long time because they aren't electrolytic. It's common for this kind of streetlight ballast to last decades, and many of them are still around today.

However, with LED, it's another story.

In a LED streetlight, electronic ballasts are used. Why don't they use magnetic versions? There are a couple reasons, but they aren't important enough to talk about here. As you may know, "electronic" usually means the item in question uses electronic components. This is where the trouble begins. LED streetlight luminaires are used outdoors, or they wouldn't be called streetlights. Protecting the circuit board in their electronic ballast from corrosion is a tricky task. One option is to use epoxy resin plastic, but that might not be such a good idea. When the epoxy hardens, it becomes very hard to work with. For many applications, this is an awesome thing. Tne problem is, dissolving it requires powerful solvents, and doing this may destroy the electronics you were trying to get to if you were trying to repair the LED driver. Recycling may also be a problem with electronic drivers. Epoxy resin takes a lot of effort to remove and e-waste recycling, generally speaking, has to be quick and efficient to be economical. Let's check out the other option, a bare circuit board. The biggest problem with using a bare circuit board (not coated in epoxy resin) is corrosion. Because streetlights are used outside, moisture can get in and do its dirty work on the components that lay inside. Defending against this problem is hard, and not doing it well increases early failures if the components break down because of the corrosion. When done well, the problem of corrosion will be stopped, but the trade-off for this will add to the total fixture cost. A Potential Idea: Perhaps a conformal coating could be used. \

Also, these anti-corrosion methods I talk about all add to the total fixture cost, and higher costs make LED less economical to use.

Sub-problem: Life Ratings

Many LED fixtures are rated to havr a life of many tens of thousands of hours. It's one of the most commonly marketed features, and many people trust this rating to be accurate. The thing is, these ratings make a few not-sosavory assumptions. What are they? Here's one of them:

Projections of future failures. I don't doubt math, but until these extrapolations are made public, be careful about them. How do we know that there aren't going to be more failures from something that wasn't accounted for?

I'll be sure to add more later.

Problem 3: Optics

Put simply, LED streetlights commonly suffer from a lack of good, non-glaring optics. Compared to HID fixtures, outdoor LEDs seem to skimp on the optics to save costs and make them more efficient.

There are a few models of LED streetlights that have better optical systems, but even these sometimes can't beat a standard streetlight.

Also, bad optics means that glare can be higher, and for drivers, this is an important problem.

There are many manufacturers of LED streetlights and related fixtures. However, the parts used in one fixture can't be swapped out with another one's. How do we know this? We know because:

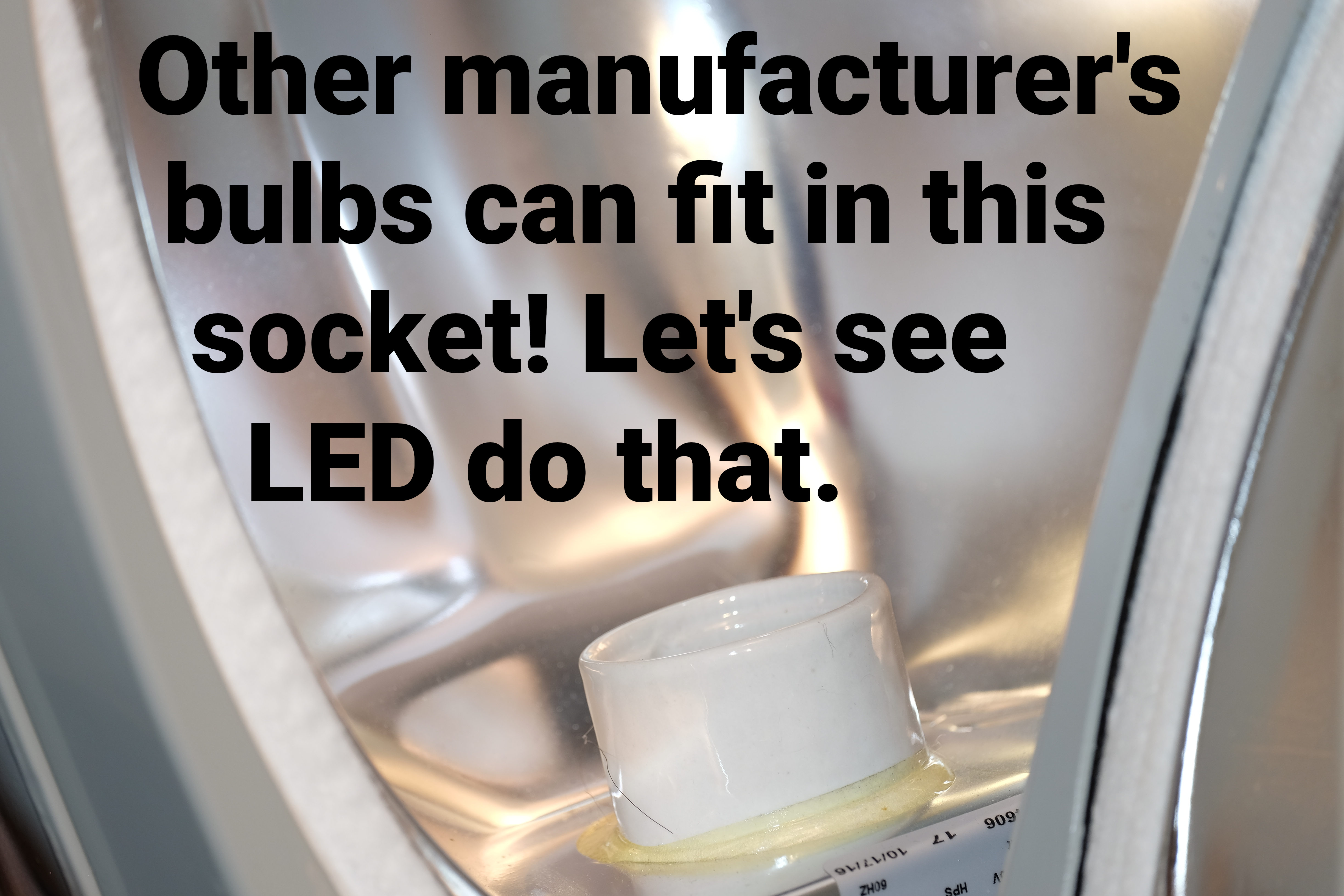

1. To power the LEDs, a specific driver is needed. Many combinations of volts and amps can be realized, and going higher or lower than what is specified can result in either a lower light output, or a shorter life from the LEDs because of extra heat. Adding to this, HID lamps come in a few pre-defined watts with set voltage and currrnt ratings. A 70-watt HPS bulb can be used in many 70-watt fixtures, but with LED you need to keep track of the voltage and current, as well as the watts. 2. To connect the LEDs, there are many options. You can use DC power connectors which come in many sizes and shapes, or even bare wires and simple spade connectors. However, with HID, due to the conditions involved, either bare wires or spade terminals are used, both of which are common or easy to get. 3. To hold in the LEDs, you'll need a circuit board. But what should it look like? What about the placements of the diodes? That's the problem, a luminaire maker can choose whatever, but unless they're all the same, it creates an effect of "locking-in" which requires a fixture owner to use only one manufacturer. What about HID? For this, it's as simple as something like a table lamp. A socket is connected to an optical compartment where a bulb fits in. It doesn't depend on who made the bulb, but rather on how it acts electrically.

Problem 5: Waste

As you saw in Problem 4, compatibility is an issue. what does it mean elsewhere? More waste! How do we know? What is a HID lamp and its LED version made of? For plain old HID, the answer is this: glass, metal, ceramic. For LED, the answer is this: plastic, fiberglass, metal. The real problem lies in how they're used. With your standard HID bulb, the glass envelopes an arctube made of the ceramic supported by metal. How i can it be reused or recycled? It seems like the glass could be reused (better than recycling by the order of reduce, reuse, recycle) because the only thing keeping the internals inside is a metal base on the bottom, and by the fact that glass items are reused all the time (read: old-school milk bottles). What about LED? To extract the LEDs off, desoldering is required. To desolder, either a special braid is used, or a special desoldering pump is used. This sounds similar to the glass bulb, but the real trouble is what happens after that. What's the end product after desoldering? A bare circuit board. Why isn't desoldering done more often? The main reasons seem to be either it's long and slow to do, or that the PCB can't be reused because of solder pad issues. If the board is reused, this would lead us to think that there's a lower reliability, and this isn't what we want in a streetlight.

Extra Note: Energy Consumption

While LED lighting may save energy, this sometimes means lower light levels.

The efficacy/efficiency of traditional streetlights is often said to be lower than it actually is.

If we have a 250 watt HPS bulb with 28000 lumens, and the optics has an efficiency of 75%, we still have 21000 lumens of pleasant light.

Then if the total fixture wattage is 300 watts (because of the ballast) we have a 70 lumens per watt efficiency. This might look like it has a bad efficiency,

but it makes up for this as you're getting excellent light control, this means the light is going where it should.

In short, here are some reasons why LED streetlights are such a big problem:

1. Most of the old streetlights work perfectly fine! Try to imagine throwing out your refrigerator just because something is marketed to be "new" and "more efficient", but the new one can't be repaired and doesn't last as long.

2. Generally speaking, LED has higher glare and often lower light levels compared to the older lighting. Do you want dimmer streets that hurt your eyes? Because that's what you might get.

3. The high blue content causes impaired sleep. It's a lot like constantly staring at a smartphone, which isn't a very healthy thing to do.

4. LED lights often look uglier compared to what they are replacing. Some of them look like something you might find on an alien planet!

Because of this, the aesthetics of them sometimes ruins the looks of an area.

5. With the regular streetlights, you can change out the lamp. But with the LEDs, it's usually trickier to change out its components because of the non-standardization.

5. With the regular streetlights, you can change out the lamp. But with the LEDs, it's usually trickier to change out its components because of the non-standardization.6. Compared to a sodium streetlight, they cause light pollution that can't be easily filtered out, leaving astronomers unhappy. That's because of LED's continuous spectrum, compared to a HPS one with a few defined lines of light.

7. White LED is more harmful to sea turtles than HPS (High Pressure Sodium) or LPS (Low Pressure Sodium),

and this is because it has a lot of blue light.

8. Many of them are made cheaply, making it harder to find a good-quality fixture.

9. LED streetlights often have bad optics, and only light up a small area, not the whole road. This also creates substantially higher amounts of light trespass. The traditional streetlights almost always have better optics, allowing for better control of the light.

All of this adds up to LED lights creating poorly-lit streets with stark light, and a lot of this isn't just for roadways, it also applies to your yardlights too.

Bonus: A video of a flashing LED streetlight. At the time the video was taken, this luminaire wasn't even 5 years old yet.